Stirling Engine Analysis Software

A beneficial optimization tool for Stirling engines

Stirling Engine Analysis Software

A beneficial optimization tool for Stirling enginesWhat Nlog does

I- Enter following variables into Nlog GUI:

- Stirling machine type.

- Geometry properties of all gas transferring channels, pipes, and chambers.

- Wetted wall surface areas and roughness factor for each.

- Regenerator type, geometry and porosity.

- Non-Ideal working gas properties

(Including compressibility factor, fluid thermal conductivity and viscosity relations).

- Engine initial charge pressure and local temperatures.

- Heat exchangers wall temperature gradient (Constant along time period).

- All of linear or rotating moving part’s mass and rotary inertia.

- Stiffness of springs if connected to any of moving parts, neglecting spring mass.

- Geometries of linkages between engine moving parts (If exist).

- External time varying force/torque applied to the engine.

II- Start software kernel and wait for about 30 minutes.

- Initial condition calculation

- Kernel process

III- Receive Nlog outputs:

- Engine output power and efficiency.

- Pressure against total volume.

- Heat transfer rate against time.

- Working gas velocity in pipes and channels.

- Rigid bodies velocity against time.

- Temperature of working gas at any point of your engine against time.

- Density of working gas at any point of your engine against time.

and much other useful information about your engine working fluid behavior and dynamics...

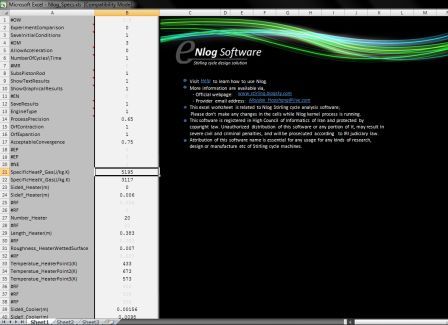

Nlog GUI (Microsoft excel based):

Nlog graphical output example: (P-V diagram)